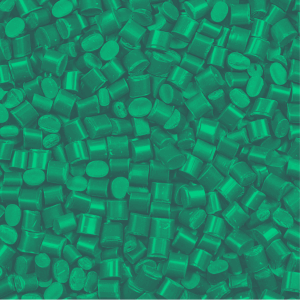

We have been operating in the plastics industry for over 20 years. We focus on recycling secondary raw materials from which LDPE, LLDPE and HDPE regrind is produced.

We are engaged in the professional production of film and waste bags using the best materials. We are a company with many years of experience – we have learnt the requirements of the market, the needs and expectations of our customers and the necessary quality standards in great detail.

What distinguishes us from the competition is continuous investment in the latest technologies, equipment and machinery as well as in our own development and skill set improvement. We care about the quality, durability and reliability of our products.

We value long-term, partnerships. Thanks to very good technical parameters of our products and excellent service, our customer numbers are rapidly growing – currently we operate on a Polish and European scale. Get to know our product range.

Since the beginning of our business activity, the team has been growing steadily. We managed to find people for whom work is a passion, not an unpleasant duty.

The efficient functioning of the company would not be possible without a harmonious team. Resaco is people. What unites us? Willingness to develop, expand our knowledge and our own horizons and introduce innovative solutions.

We feel responsible for the environment around us. We undertake a number of activities and initiatives aimed at reducing the negative impact of our company on the environment. Environmental education in Resaco is of the highest level and each employee knows how important environmental protection is as an aspect of the company's activity.

Our bags are made of recycled materials – regrind, which is produced by our partner company – Zakład Usługowy Recyklon Piotr Radosz Spółka Jawna.

"Recyklon" takes waste in the form of film from specialised companies from provinces all over Poland that collect waste. It produces regrind from the waste and we produce bags from the regrind. By manufacturing film from recycled materials, we limit the use of our planet's natural resources; such actions have a very significant impact on the environment.

The history of our group began 20 years ago and that is when Recyklon was founded. The factory has been recycling plastics from the very beginning. For years we have specialised in recycling and processing LDPE film. Gaining a lot of knowledge in the recycling industry was instrumental in the decision to combine recycling with bag and film production. Taking care of LDPE and HDPE raw materials to be recycled and reused in production has become a superior value for the company owners. In 2013, Resaco was established and they continued to produce film and bags. This period initiated very dynamic development of both companies, which continues to this day.

Did you know that recycling 1 kilogram of plastic reduces carbon dioxide emissions by 2 kilograms compared to using primary raw materials? Climate change is a serious problem nowadays. Specific measures are needed, taken not just by individuals, but by society as a whole. Both individuals and companies, in our opinion, have a responsibility to take care of the environment by choosing the most efficient solutions.

We have been operating in the market for over 20 years. We carry out all orders maintaining the highest quality standards.

We have been operating in the plastics industry for over 20 years. We focus on recycling secondary raw materials from which LDPE, LLDPE and HDPE regrind is produced.

For years we have been focusing on modern solutions, innovative machines and employee development. We are constantly trying to expand our business.

We have gained considerable experience in the recycling of plastic waste and that is what determined the decision to combine recycling with the production of packaging – that is how Resaco Sp. z o.o. was born. Today we serve customers from all over Poland and Europe.

© Copyright 2019 RESACO All Rights Reserved | Privacy Statement